Designed for customized parts processing

IDMockup custom 3D printing services are designed to meet a wide range of customer needs, from rapid prototyping to large-scale part production. We deliver 3D printed components and samples quickly and accurately. Our core 3D printing technology is Stereolithography (SLA), which ensures the highest quality results, minimizes tolerances, and optimizes surface finishes to meet customer specifications.

Key Features of Our Process:

⚡ Plastic Materials: We primarily use “ABS-like” materials (yellow resin), which offer excellent hardness, toughness, impact resistance, and heat resistance. These are ideal for structural components and sample testing in industries such as home appliances, electronics, automotive, and medical devices.

⚡ Metal Printing Available: We can switch materials to print metal parts.

⚡ Maximum Build Size: 600 x 600 x 400 mm, utilizing industrial-grade machines rather than desktop 3D printers.

Advantages of Our Method:

⚡ High Customization and Rapid Prototyping: 3D printing allows for quick product validation, testing, and provides rapid manufacturing solutions for customer products.

⚡ Production of Complex Shapes: 3D printing can create intricate structures that traditional manufacturing methods cannot, such as undercuts.

⚡ Material Waste Reduction: As a layer-by-layer additive manufacturing process, 3D printing minimizes material waste, unlike CNC processes that generate excess material.

⚡ Lower Mold Costs: 3D printing reduces mold development time and costs, speeding up product validation and facilitating rapid market entry for new products, including small-batch production.

If customers do not have 3D files (such as .stl, .stp, .step, .igs), we can also assist by 3D scanning physical samples to create a digital model. Using a combination of 3D printing and silicone molding techniques, we can reverse engineer and recreate identical physical samples.

| SLA (Stereolithography) | SLS (Selective Laser Sintering) | DLP / LCD light curing surface projection | FDM hot melt lamination | |

|---|---|---|---|---|

| Forming principle | UV laser curing liquid resin point by point | 1) Fiber laser molten metal powder (SS, Ti‑6Al‑4V, AlSi10Mg…) 2) CO₂ / Fiber laser sintered nylon powder | Projected surface light cures one layer of resin at a time | Hot melt extrusion plastic wire |

| Layer thickness (µm) | 25–100 | 30–60 (metal) 80–120 (nylon) | 35–60 | 100–300 |

| Dimensional accuracy | ±0.05 mm / 100 mm | ±0.05 mm / 50 mm (metal) ±0.15 mm (nylon) | ±0.05–0.1 mm | ±0.2–0.3 mm |

| Surface roughness (Ra) | 0.8–1.5 µm (almost mirror-like) | Metal: 4~6 µm (2 µm after sandblasting) Nylon: 6~10 µm (<5 µm after sandblasting) | 1–2 µm | 10–25 µm (staircase pattern) |

| Available Materials | Transparent, ABS-like, elastic, heat-resistant, medical resin | Metal: stainless steel, aluminum, titanium, nickel-based alloy, tool steel Nylon: PA12, PA11, carbon fiber/glass fiber reinforced nylon | The resin is similar to SLA, but batch change is troublesome | PLA, ABS, PETG, TPU |

| Print speed | Slow | Medium (scan but can be stacked) | Fast (whole layer flash solid) | Fast (large layers but slow cooling) |

| Unit cost | Middle | Medium-High | Low‑Medium | Low |

| Advantages and Disadvantages | • Best details & surface in the industry • Can be used for transparent, precision medical, microfluidics • Slower printing speed, but the highest precision | • High density, strong mechanics, no support → Insert/free hollow • No support, excellent toughness , can be directly used as buckle, hinge and functional parts •High batch stacking efficiency | • One layer solidified at a time → Faster than SLA • Product production efficiency is high and cheaper, but still rougher than SLA, toughness and brittleness are still not as good as SLA | • Cheap to install, consumables are widely available but need to be replaced frequently • DIY & teaching mainstay |

| IDMockup Main Service | ✅ | ✅ | ❌ | ❌ |

Scope of Services

We create realistic product models or prototypes based on customer-provided requirements and drawings. These models accurately replicate the intended design, allowing for detailed evaluation and testing before moving to mass production.

Enables small-scale mass production of the same parts

We provide just-in-time production based on customer needs, minimizing storage and inventory costs. This approach ensures efficient production while reducing overhead related to warehousing and excess stock.

Basic Processing Materials for 3D Printing

Plastics

ABS is strong, durable, and offers good heat resistance and impact resistance, making it a preferred plastic for general parts and consumer products.

Common material choices:

◆ ABS-like (Yellow-Green Color) – Stronger and more endurable structure

PA (Nylon) is widely used, strong, and wear-resistant, making it ideal for gears, bearings, and other high-wear surfaces.

Common material choices:

◆ PA12 White

◆ PA12 Black

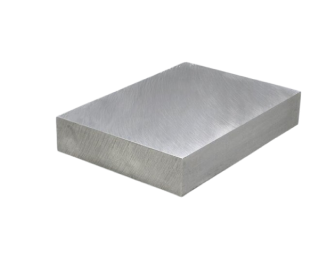

Metals

Aluminum is lightweight yet strong, easy to machine, and corrosion-resistant, making it commonly used in aerospace and automotive industries for lightweight components.

Common material choice:

◆ AL6061

Stainless steel is renowned for its corrosion resistance and is commonly used in medical devices, robotics, and automated manufacturing equipment.

Common material choice:

◆ Stainless 316L

CMF Options

We provide a wide range of materials, including metals, plastics, and composites.

We offer superior surface finishes that enhance part durability and aesthetics for applications requiring smooth or textured surfaces.

Applied Industries

IDMockup offers top-notch manufacturing capabilities, whether for rapid prototyping or custom production orders. Our self-owned factories and satellite factories are equipped to efficiently produce complex, high-quality parts.

👉 For more about our latest news, technology and equipment, please follow our official Facebook, X (Twitter) and official blog!