汐紫模型目前提供客户各类外型效果选择,满足所有客户多样需求。

为了提供高质量的产品,设立了许多测试仪器及检测系统以维持质量!

基本后处理

塑料

在塑件表面喷涂 2K PU、烤漆丙烯酸或静电喷涂聚酯粉,形成 15 – 60 µm 的彩色保护膜。粉体一次成膜 60 µm,无溶剂更环保

.

适用材料:ABS、PC、PC/ABS、PBT、PA;PP / PE 需底漆或电晕活化

优点:色彩/光泽自由 (可搭配Pantone色号)、耐候 500 h↑、修补容易;粉体冲击韧性高

缺点:需烘烤 120 – 160 °C(热变形风险),粉体对细字不易控边

利用溶剂比例与消光剂调整同一 PU / UV Clear 可得到 95 GU 镜面或 < 10 GU 丝绒哑光

.

适用材料:ABS、PC、PMMA、ASA、PC/ABS

优点:高级外观、流平佳、哑光可遮微刮

缺点:亮光怕指纹、哑光怕沾污;烘漆增加周期

在 Clear 漆中加入弹性粒子 (TPR / Silica) 做 Soft‑Touch;或加入高交联 UV 漆配方做 3H – 6H 硬化层

.

适用材料:ABS、PC/ABS、TPU(表涂)、PMMA

优点:柔肤不滑、耐汗蚀;硬化漆提高透明件抗刮

缺点:Soft‑Touch 抗化学性差;硬化漆需紫外设备

含铝粉、云母珠光或银铜微片的 PU 漆;导电漆再加碳粉或镍铜片,表面电阻 < 50 Ω

.

适用材料:ABS、PC、PBT、PA

优点:镜面金属感、省去电镀;导电漆 EMI 屏蔽 60 dB↑

缺点:金属漆需罩光漆防氧化;导电漆成本高、容易掉粉

模具化学蚀刻、塑件喷砂或砂带拉丝得到皮纹、细砂、发丝纹

.

适用材料:几乎所有热塑性;PC/ABS、ABS 最佳

优点:遮盖射出流痕,耐指纹;无额外涂层

缺点:改纹需重修模;发丝方向固定

化学铜活化 → 电镀铜/镍/铬或真空 PVD Al,厚度 0.3 – 20 µm

.

适用材料:★ABS、★PC/ABS;PC、PA、PBT 经等离子+底漆亦可

优点:镜面、耐磨、金属质感极佳;EMI 导电

缺点:六价铬环保压力;导致尺寸增厚 30–70 µm

网版厚膜油墨或 PAD 印曲面;水转印膜+活化剂把碳纤/迷彩图案包覆立体件

.

适用材料:ABS、PC/ABS、PA、PP(需电晕)

优点:多色 LOGO、全幅花纹大曲面一次成型

缺点:网印只能平 / 小曲面;水转印需二次清漆封孔

热熔胶膜+真空包覆或 Back‑Injection 射出

.

适用材料:底件 ABS、PC;包覆层布、PU 皮、超纤

优点:豪华触感、透气、隔热降噪

缺点:边角易起皱;热循环 > 80 °C 可能脱层

金属或硬塑嵌件,射出第二料 TPU/TPV;或 2‑Shot 硬 PC + 软 TPE

适用材料:PC+TPE、ABS+TPU、PA+TPV

优点:防滑、防水、吸震;结构强度 + 柔软握感一次成型

缺点:模具复杂、注射设备成本高;相容性配料受限

120 – 160 °C、2 – 5 bar 把金属光泽薄箔热压转印

适用材料:ABS、PC/ABS、PMMA、AS;PP 须底胶

优点:镜面金、银、全息彩虹;无重金属废水

缺点:仅平面或大曲面;耐磨性低于电镀

光纤或 UV 雷射汽化表层,形成永久文字、图案或透光层

–

适用材料:ABS、PC、PA、PMMA(加助剂可改善效果)

优点:无墨耗、耐久、精度 30 µm;图标可透光背光

缺点:一次性,不可改色;深色塑料效果最佳,浅色需添加雷射母粒

金属

在除油、喷砂或化成处理后,使用喷枪把 20 – 40 µm 的色漆或透明漆均匀覆在金属表面,80 – 160 °C 烘烤或室温固化

.

适用材料:铝合金、不锈钢、碳钢、锌压铸、镁合金

优点:色彩、光泽、触感自由度最高;工装简单;可局部修补

缺点:耐磨、耐溶剂性取决于漆种;厚度不均或“橘皮”需重喷;VOC 排放须设备

以电化学或物理汽相方式在金属件表面沉积 0.3 – 30 µm 镍、铬、铜、DLC、TiN 等金属层,提供装饰与功能

.

适用材料:锌压镶件(最易)、钢、铜、铝(需锌置换层)、镁(需镍封闭)、不锈钢

优点:镜面金属质感、硬度高、耐磨、可导电;PVD 无六价铬

缺点:镀液环保压力大、工序复杂;尺寸加 10 – 70 µm,需设计补偿

铝或镁作阳极,在硫酸或磷酸槽内生成 5 – 25 µm Al₂O₃,多孔层可吸附染料并封孔

.

适用材料:铝合金(6xxx / 7xxx 最佳)、镁合金(需微弧阳极 MAO)

优点:耐腐、耐磨、色彩均匀;不增加尺寸,反而缩 2 µm 内

缺点:只适用含阀金属;硬阳极需 ≥ 60 °C 冲洗封孔,色泽有限

静电喷涂聚酯、环氧‑聚酯或氟碳粉末,180 °C×10 min 熔融流平一次成膜 60–100 µm;或传统烘烤丙烯酸色漆

.

适用材料:铝、锌、钢、不锈钢(需磷化)

优点:厚膜、耐 UV、耐冲击,覆盖边角;粉体 100 % 利用率零 VOC

缺点:高温烘烤对薄铝件有翘曲风险;细字锐边易被粉体圆角掩盖

以石英砂、玻璃珠或百洁布轮对金属进行粗化或线性刷纹,Ra 可控 0.6 – 4 µm

.

适用材料:所有金属;对硬度 HRC > 45 的钢需选碳化矽砂

优点:去除刀痕、均匀哑光、提高油漆附着;拉丝具有高级发丝纹

缺点:尺寸微缩;拉丝纹有方向性,转角不连续;砂表面容易藏污

网印厚膜油墨(或移印)在金属上印 Logo、尺规;水转印利用 PVA 薄膜+活化剂一次转印整面图案

.

适用材料:铝、不锈钢、镀铬锌件(先喷底漆);转印需喷底色+罩光

优点:网印成本低、色彩精准;水转印可覆盖不规则曲面、木纹/碳纤图

缺点:网印受平面限制;水转印需二次清漆封孔、膜接口难隐藏

金属作嵌件,射出 TPU/TPE,也可热熔胶加压或 PU 倒灌

–

适用材料:基底铝、不锈钢、锌压铸;包胶 TPU、TPE、矽胶

优点:防滑、防震、密封;金属强度 + 橡胶手感兼得

缺点:金属需开倒扣孔,追加 CNC 成本;射出温度 200 °C 以上对镀层有风险

在金属表面先喷 10–20 µm 透明底漆,120 – 160 °C/2–5 bar 把金/银/全息箔热压转印

.

适用材料:阳极铝、不锈钢、镀镍锌件

优点:镜面金属光、局部装饰、无镀液废水

缺点:仅适合平面或大曲面;耐磨性低于电镀与 PVD

用光纤、CO₂ 或 UV 雷射汽化金属表层或诱导氧化,形成 30–300 µm 深的凹刻或黑化标记

–

适用材料:所有金属;阳极铝、黑化不锈钢效果最佳

优点:永久、不掉色、解析度 < 30 µm;序号、LOGO、防伪

缺点:无法改色;过强可能熔穿薄壁或影响镀层

将工件接阴极或阳极,在水性环氧/丙烯酸槽中施加 60 – 400 V,使带电树脂均匀析出并 180 °C 烘固

–

适用材料:碳钢、不锈钢、铝、锌压铸(前处理磷化/陶化)

优点:全覆膜 (含内腔)、防锈 1 000 h+、膜厚可控 10–25 µm;可作底漆再喷色漆

缺点:只能单一颜色(黑、灰);设备投资大,需纯水+废水处理

基本加工材料

塑料

ABS 坚固、耐用,并具有良好的耐热性和抗摔性,通常是一般零件或消费性用品塑料首选。

.

🔧常见材料选择及可搭配工法 :

ABS 原色/白色/黑色 – CNC加工、真空注型、快速模具、低压灌注

ABS+PC 黑色/白色 – CNC加工、真空注型、快速模具、低压灌注

类ABS (黄绿色) – 光固化3D打印

.

⚙️材料基本物性:

◆ 燃烧性: 可燃,变形温度95-112摄氏度

◆ 优点: 外观佳、价格合理、电镀特性优、低温耐击性优、成形后收缩率小、尺寸精度优、抗酸碱性优

◆ 缺点: 耐候性差、可溶于溶剂

PC (聚碳酸酯) 极为耐用,具有高防摔性和良好的透明度。

.

🔧常见材料选择及可搭配工法 :

PC 透明/白色/黑色/加玻璃纤维GF – CNC加工、真空注型、快速模具、低压灌注

.

⚙️材料基本物性:

◆ 燃烧性: 自消性

◆ 优点: 强韧耐冲击、耐热耐寒性优、尺寸精度强、安定性强、耐候性强、具透明性

◆ 缺点: 耐疲劳性差、抗紫外线弱、抗碱性弱

PMMA (压克力,或丙烯酸) 以其水晶般透明度及耐候性而闻名。

.

🔧常见材料选择及可搭配工法 :

PMMA 透明/白色/黑色 – CNC加工、真空注型、快速模具、低压灌注

.

⚙️材料基本物性:

◆ 燃烧性: 可燃,变形温度71-91摄氏度

◆ 优点: 透明性优、硬度高、光泽度优、耐候性优、成行性优、电气性优

◆ 缺点: 耐冲击差,易有伤痕、可溶于溶剂

POM 强度高、表面摩擦低、尺寸稳定性好,非常适合用于机械中精密零部件。

.

🔧常见材料选择及可搭配工法 :

POM 白色/黑色 – CNC加工、真空注型、快速模具

.

⚙️材料基本物性:

◆ 燃烧性: 可燃,变形温度160-170摄氏度

◆ 优点: 强韧、富有弹性、耐疲劳性优、摩擦抵抗小、耐药品性、耐热性优

◆ 缺点: 抗紫外线差、抗强酸力差

尼龙用途广泛、坚固且耐磨擦,通常用于齿轮、轴承和其他耐磨表面。

.

🔧常见材料选择及可搭配工法 :

PA6 / PA12 / PA66 (可加玻璃纤维GF) – CNC加工、真空注型、快速模具、低压灌注

.

⚙️材料基本物性:

◆ 燃烧性: 自消性,变形温度约127-182摄氏度

◆ 优点: 强韧、耐冲击、摩擦抵抗小、耐热耐寒性优、耐药品性优、耐油性优

◆ 缺点: 吸水性大,缺乏尺寸安定性、抗强酸力差

PE (聚乙烯) 质轻,具有较高防摔能力,广泛用于包装容器上。

.

🔧常见材料选择及可搭配工法 :

PE 黑色/白色 – CNC加工、真空注型、快速模具、低压灌注

.

⚙️材料基本物性:

◆ 燃烧性: 可燃,变形温度60-80摄氏度

◆ 优点: 耐摔性优、卫生无毒、耐水性优、耐药品性优、电气特性优

◆ 缺点: 耐热性差、耐候性差、成形后收缩大

PEEK 因其耐高温性和强度而闻名,常用于半导体、航太和医疗器材制造中。

.

🔧常见材料选择及可搭配工法 :

PEEK 原色/黑色 – CNC加工、真空注型、快速模具、低压灌注

.

⚙️材料基本物性:

◆ 燃烧性: 可燃,变形温度200-316摄氏度

◆ 优点: 耐温高、抗化学性优、抗辐射性优、耐磨损耐磨擦优、高强度、耐水解性优、电绝缘性优

◆ 缺点: 抗冲击低、尺寸稳定性不佳、抗紫外线差

PP (聚丙烯) 坚韧,具有优异的耐化学性,常用于会接触化学溶剂的零件及容器包装上。

.

🔧常见材料选择及可搭配工法 :

PP 黑色/白色/加玻璃纤维GF – CNC加工、真空注型、快速模具、低压灌注

.

⚙️材料基本物性:

◆ 燃烧性: 可燃,变形温度99-110摄氏度

◆ 优点: HINGE特性优、耐热性优、塑胶中最轻、电气特性优、耐药品性优

◆ 缺点: 低温耐冲击性差、耐候性差

HDPE 以其高强度密度比、防撞性而闻名,常用于瓶子(我们也可用于吹塑成型)或耐腐蚀管道制造上。

.

🔧常见材料选择及可搭配工法 :

HDPE 黑色/白色 – CNC加工、真空注型、快速模具、低压灌注、吹塑成型

.

⚙️材料基本物性:

◆ 燃烧性: 可燃,变形温度60-82摄氏度

◆ 优点: 耐摔性优、卫生无毒、耐水性优、耐药品性优、电气特性优

◆ 缺点: 耐热性差、耐候性差、成形后收缩大

橡胶因其柔韧性和灭震性受到重视,非常适合需要承受持续弯曲和压力的密封件或垫圈等产品。我们也可以对于制作橡胶之硬度进行调整。

电木是一种高硬度、耐高温的热固性塑料,具有良好的绝缘性和耐化学性。它常用于制造电气元件(如开关、插座)和机械零件,特别适合用于要求耐热和绝缘的环境中。

🔧常见材料选择及可搭配工法:

电木 – CNC加工、压缩成型

⚙️材料基本物性:

◆ 燃烧性: 可燃,变形温度 150-200 摄氏度

◆ 优点: 高耐热性、绝缘性能优异、耐化学性强、尺寸稳定

◆ 缺点: 脆性高、易破裂、无法回收、加工难度较高

铁氟龙是一种化学稳定性极高的热塑性材料,以其优异的耐高温性和极低的摩擦系数闻名,广泛应用于耐腐蚀管道衬里、密封件和绝缘层等需要高耐化学性的领域。

🔧常见材料选择及可搭配工法:

铁氟龙 (PTFE) – CNC加工、车削加工、压缩成型、机加工

⚙️材料基本物性:

◆ 燃烧性: 不燃,持续使用温度约为 -200 到 260 摄氏度

◆ 优点: 优异的耐高温性、极低的摩擦系数、化学稳定性强、不吸水、电气绝缘性能佳

◆ 缺点: 成型加工难度高、刚性低、承载能力有限、热膨胀系数大

金属

铝重量轻但强度高,易于机械加工且有耐腐蚀性,常用于航太及汽车等需要轻量化的零部件上。

.

🔧常见材料选择及基本物性 :

AL6061 – 热处理型耐腐蚀合金,加工性好、焊接性好

AL6063 – 挤压用合金,强度低

AL5052 – 中等强度合金,加工性好、抗疲劳度佳、抗海水腐蚀高

AL5083 – 镁含量高、硬度高、耐海水腐蚀高

AL7075 – 强度较高较硬,具良好机械性与阳极反映

ADC 6, 10, 12 – 常用铝合金铸造材料

.

⚙️适用加工工法(非全部以上材料选择都适用):

◆ 基本可加工工法: CNC加工、放电加工、挤型、压铸

锌具有良好的耐腐蚀性、流动性且易于CNC机械加工,常与其他金属铸为合金加工。

.

🔧常见材料选择及基本物性 :

Zamak 3 – 机械性能好,具良好的流动性,是压铸首选

Zamak 5 – 机械性能好,具良好的流动性

Zamak 2 – 机械性能好,硬度最硬,但尺寸精度不高

ZA-8, 12, 27 – 是为锌铝合金,有高硬度、抗磨损抗变形力

.

⚙️适用加工工法(非全部以上材料选择都适用):

◆ 基本可加工工法: CNC加工、放电加工、金属挤型、金属压铸

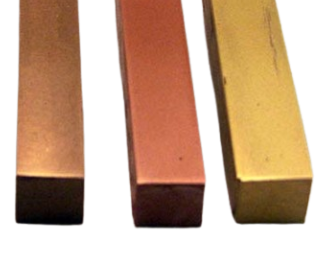

铜以其优越的导电性和热性能而闻名,常用于电气元件之中。青铜(铜与锡合金)则具有高耐腐蚀性和耐金属疲乏性,常用于轴承、衬套及船用五金。黄铜(铜与锌合金) 耐用且摩擦系数低,适合制作高精确度的零部件及工具。

.

🔧常见材料选择及基本物性 :

C1100 (红铜) – 高导电性、导热性、延展性、耐腐蚀性、耐候性

C17300 (铍铜) – 耐热性高、热处理前具延展性、热处理后具机械强度、耐疲劳性、高导电性

C2700 (黄铜) – 冷间锻造性、延展性、适于机械零件

C5191/C5441 (青铜) – 耐疲乏性好、耐腐蚀、耐磨损

C6782 (黄铜) – 热间锻造性、强度高、耐腐蚀

ZQA19-2, 4, 7, 10 – 适合铜压铸造

.

⚙️适用加工工法(非全部以上材料选择都适用):

◆ 基本可加工工法: CNC加工、放电加工

铝镁合金具有和钢一样的强度及硬度,但重量比钢轻许多,与塑胶接近。具备良好热传导力,常用于散热的电子器材及外壳等。

.

🔧常见材料选择及基本物性 :

AZ31 – 具抗震性、吸热性、耐油性

AZ61 – 质量较轻,比AZ31含有更高的铝成分

AZ91D – 最普遍的镁合金,有高强度和良好铸造性能

AM60B – 除高强度与铸造性能外,更有良好延展性与吸震性

.

⚙️适用加工工法(非全部以上材料选择都适用):

◆ 基本可加工工法: CNC加工

不锈钢以耐腐蚀性而闻名,常用于医疗设备、机器人、自动化加工设备等。

.

🔧常见材料选择及基本物性 :

SUS304, 316 – 具高硬度和耐腐蚀程度,不易生锈,是普遍的食品级及医疗级用途的材质

SUS201 – 具基本硬度和耐腐蚀程度,但易生锈

SUS420, 430, 431 – 具基本硬度和耐腐蚀程度,但具磁性

.

⚙️适用加工工法(非全部以上材料选择都适用):

◆ 基本可加工工法: CNC加工、放电加工

钛具有金属中最高的强度密度比,也具有高耐腐蚀和耐疲乏性,常用于航太、医疗器械等设备工具上。

.

🔧常见材料选择及基本物性 :

TA1 / TA2 (工业纯钛) – 机械性能与化学性能与不锈钢相似,但强度相对较弱,易于加工成型,冲压焊接佳,亦有良好抗腐蚀抗氧化性

TC4 / Ti-6Al 4V (钛合金) – 可用于锻造、冲压焊接,有良好耐热性、抗腐蚀性

.

⚙️适用加工工法(非全部以上材料选择都适用):

◆ 基本可加工工法: CNC加工、放电加工

碳化硅具仅次于金刚石的高硬度和耐磨性,同时耐高温、耐磨损、耐腐蚀,具高热传导力。常用于半导体制造零部件、耐火板、陶瓷轴承等设备上。

.

🔧常见材料选择及基本物性 :

SiC – 高硬度高耐磨、化学性能及机械性能稳定、低耗能高功率

AlSiC – 材料轻,和铝相似,但抗弯强度和钢材一样,抗震性佳,具高热导低热膨胀

.

⚙️适用加工工法(非全部以上材料选择都适用):

◆ 基本可加工工法: CNC加工、放电加工

👉 更多有关我们的最新消息,请关注我们的官方Facebook 、X (Twitter)平台及官方博客!