Designed for customized parts processing

Reaction Injection Molding (RIM, a.k.a. Low-pressure casting) typically involves injecting PU (polyurethane) material into a mold under low pressure, where it forms the desired product through a chemical reaction. This process is ideal for producing medium to high volumes of complex products, offering low costs, material versatility, high strength, and cost efficiency. It is suitable for both plastic and metal components.

Key Features:

⚡ Ability to Produce Complex Shapes: Capable of manufacturing products with intricate internal structures and fine appearances, such as automotive parts with detailed designs.

⚡ Cost-Effective for Medium-Volume Production: Especially beneficial for small to medium batch production. For example, compared to some large-scale manufacturing methods, low-pressure casting is more cost-efficient for medium-to-high volume production, such as in electronic housings.

⚡ Material Versatility: A wide range of materials can be used based on performance requirements, allowing flexibility in product design and application.

Overall, RIM is widely applied in mold manufacturing, automotive, electronics, and medical fields, offering a reliable and versatile production method.

Scope of Services

We create realistic product models or prototypes based on customer-provided requirements and drawings. These models accurately replicate the intended design, allowing for detailed evaluation and testing before moving to mass production.

We can achieve medium-scale batch production of identical parts, with the mold lifespan capable of producing approximately 100,000 to 200,000 pieces.

We provide just-in-time production based on customer needs, minimizing storage and inventory costs. This approach ensures efficient production while reducing overhead related to warehousing and excess stock.

Basic Processing Materials

Plastics

ABS is strong, durable, and offers good heat resistance and impact resistance, making it a preferred plastic for general parts and consumer products.

Common material choices:

◆ ABS Plain Color/White/Black

◆ ABS+PC Black/White

PC (Polycarbonate) is highly durable, offering excellent impact resistance and good transparency.

Common material choices:

◆ PC Transparent/White/Black

◆ PC+Glass Fiber

PMMA (Acrylic) is renowned for its crystal-clear transparency and excellent weather resistance.

Common material choices:

◆ PMMA Transparent/White/Black

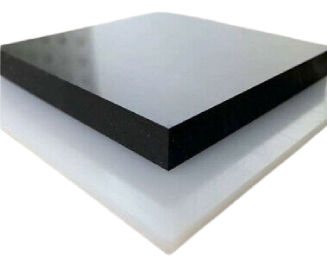

POM (Polyoxymethylene) is known for its high strength, low surface friction, and excellent dimensional stability, making it ideal for precision components in machinery.

Common material choices:

◆ POM White/Black

PA (Nylon) is widely used, strong, and wear-resistant, making it ideal for gears, bearings, and other high-wear surfaces.

Common material choices:

◆ PA6 (+Glass Fiber)

◆ PA12 (+Glass Fiber)

◆ PA66 (+Glass Fiber)

PE (Polyethylene) is lightweight with excellent impact resistance, making it widely used in packaging containers.

Common material choices:

◆ PE Black/White

PEEK is renowned for its high-temperature resistance and strength, making it commonly used in semiconductor, aerospace, and medical device manufacturing.

Common material choices:

◆ PEEK Beige/Black

PP (Polypropylene) is tough and offers excellent chemical resistance, making it commonly used in parts and packaging that come into contact with chemical solvents.

Common material choices:

◆ PP Black/White

◆ PP + Glass Fiber

HDPE is known for its high strength-to-density ratio and impact resistance, making it commonly used in bottle manufacturing (including blow molding) and corrosion-resistant piping.

Common material choices:

◆ HDPE Black/White

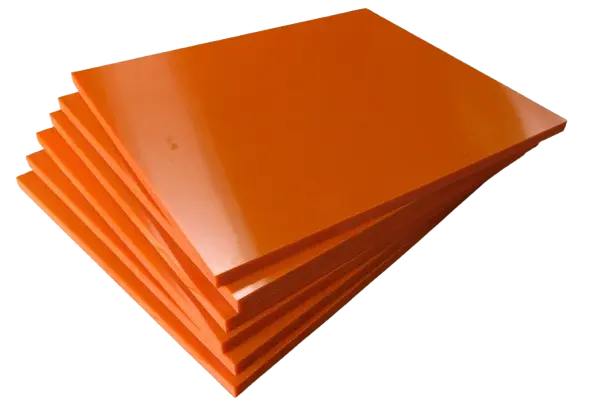

Bakelite is a high-hardness, heat-resistant thermosetting plastic known for its excellent insulation and chemical resistance. It is commonly used to produce electrical components (such as switches and sockets) and mechanical parts, especially in environments that require heat resistance and insulation.

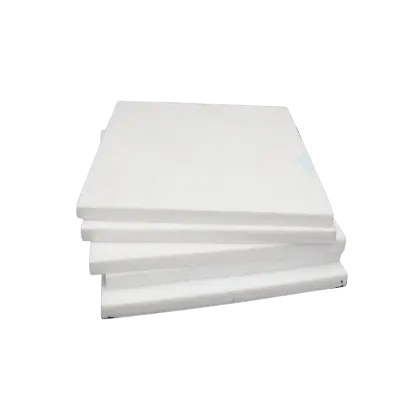

Teflon is a thermoplastic material with exceptional chemical stability, known for its high-temperature resistance and extremely low friction coefficient. It is widely used in applications requiring high chemical resistance, such as corrosion-resistant pipe linings, seals, and insulation layers.

Material Properties and Surface Options

We provide a wide range of materials, including metals, plastics, and composites.

We offer superior surface finishes that enhance part durability and aesthetics for applications requiring smooth or textured surfaces.

Applied Industries

IDMockup offers top-notch manufacturing capabilities, whether for rapid prototyping or custom production orders. Our self-owned factories and satellite factories are equipped to efficiently produce complex, high-quality parts.

👉 For more about our latest news, technology and equipment, please follow our official Facebook, X (Twitter) and official blog!