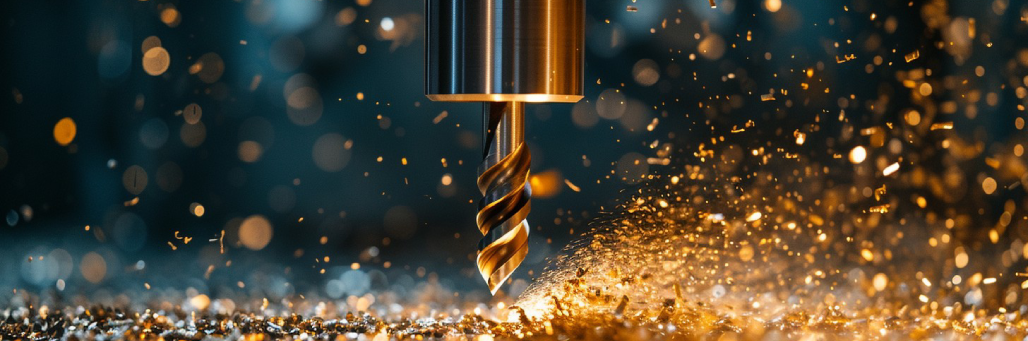

Basic processing Materials

Plastics

ABS is strong, durable, and offers good heat resistance and impact resistance, making it a popular plastic choice for general parts and consumer products.

🔧 Common Material Options and Compatible Methods:

- ABS (Natural/White/Black) – Suitable for CNC machining, vacuum casting, rapid tooling, and low-pressure casting.

- ABS+PC (Black/White) – Suitable for CNC machining, vacuum casting, rapid tooling, and low-pressure casting.

- ABS-like (Yellow-Green) – Suitable for SLA 3D printing.

⚙️ Basic Material Properties:

◆ Flammability: Combustible, deformation temperature 95-112°C.

◆ Advantages: Aesthetic appearance, reasonable cost, excellent electroplating properties, good low-temperature impact resistance, low shrinkage after molding, high dimensional accuracy, and good acid and alkali resistance.

◆ Disadvantages: Poor weather resistance, soluble in solvents.

PC (Polycarbonate) is highly durable, offering excellent impact resistance and good transparency.

🔧 Common Material Options and Compatible Methods:

- PC (Transparent/White/Black/Glass-Filled GF) – Suitable for CNC machining, vacuum casting, rapid tooling, and low-pressure casting.

⚙️ Basic Material Properties:

◆ Flammability: Self-extinguishing.

◆ Advantages: Tough and impact-resistant, excellent heat and cold resistance, high dimensional accuracy, strong stability, good weather resistance, and transparent.

◆ Disadvantages: Poor fatigue resistance, weak UV resistance, and weak alkali resistance.

PMMA (Acrylic) is renowned for its crystal-clear transparency and excellent weather resistance.

🔧 Common Material Options and Compatible Methods:

- PMMA (Transparent/White/Black) – Suitable for CNC machining, vacuum casting, rapid tooling, and low-pressure casting.

⚙️ Basic Material Properties:

◆ Flammability: Combustible, deformation temperature 71-91°C.

◆ Advantages: Excellent transparency, high hardness, superior gloss, excellent weather resistance, good formability, and good electrical properties.

◆ Disadvantages: Poor impact resistance, easily scratched, and soluble in solvents.

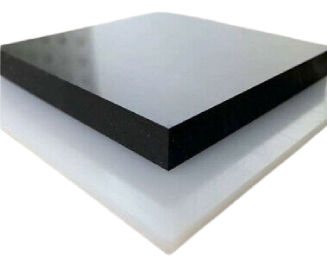

POM (Polyoxymethylene) is known for its high strength, low surface friction, and excellent dimensional stability, making it ideal for precision mechanical components.

🔧 Common Material Options and Compatible Methods:

- POM (White/Black) – Suitable for CNC machining, vacuum casting, rapid tooling, and low-pressure casting.

⚙️ Basic Material Properties:

◆ Flammability: Combustible, deformation temperature 160-170°C.

◆ Advantages: Strong and tough, flexible, excellent fatigue resistance, low friction, good chemical resistance, and superior heat resistance.

◆ Disadvantages: Poor UV resistance and weak resistance to strong acids.

Nylon (PA) is widely used for its strength and wear resistance, making it ideal for gears, bearings, and other high-wear surfaces.

🔧 Common Material Options and Compatible Methods:

- PA6 / PA12 / PA66 (Glass-Fiber available) – Suitable for CNC machining, vacuum casting, rapid tooling, and low-pressure casting.

⚙️ Basic Material Properties:

◆ Flammability: Self-extinguishing, deformation temperature around 127-182°C.

◆ Advantages: Strong, impact-resistant, low friction, excellent heat and cold resistance, good chemical resistance, and oil resistance.

◆ Disadvantages: High water absorption, poor dimensional stability, and weak resistance to strong acids.

PE (Polyethylene) is lightweight with excellent impact resistance, making it widely used in packaging containers.

🔧 Common Material Options and Compatible Methods:

- PE (Black/White) – Suitable for CNC machining, vacuum casting, rapid tooling, and low-pressure casting.

⚙️ Basic Material Properties:

◆ Flammability: Combustible, deformation temperature 60-80°C.

◆ Advantages: Excellent impact resistance, hygienic and non-toxic, superior water resistance, good chemical resistance, and excellent electrical properties.

◆ Disadvantages: Poor heat resistance, weak weather resistance, and high shrinkage after molding.

PEEK is renowned for its high-temperature resistance and strength, making it commonly used in semiconductor, aerospace, and medical device manufacturing.

🔧 Common Material Options and Compatible Methods:

- PEEK (Natural/Black) – Suitable for CNC machining, vacuum casting, rapid tooling, and low-pressure casting.

⚙️ Basic Material Properties:

◆ Flammability: Combustible, deformation temperature 200-316°C.

◆ Advantages: High-temperature resistance, excellent chemical resistance, radiation resistance, superior wear and friction resistance, high strength, excellent hydrolysis resistance, and good electrical insulation.

◆ Disadvantages: Low impact resistance, poor dimensional stability, and weak UV resistance.

PP (Polypropylene) is tough and offers excellent chemical resistance, making it commonly used in parts and packaging that come into contact with chemical solvents.

🔧 Common Material Options and Compatible Methods:

- PP (Black/White/Glass-Filled GF) – Suitable for CNC machining, vacuum casting, rapid tooling, and low-pressure casting.

⚙️ Basic Material Properties:

◆ Flammability: Combustible, deformation temperature 99-110°C.

◆ Advantages: Excellent hinge properties, good heat resistance, the lightest of all plastics, excellent electrical properties, and superior chemical resistance.

◆ Disadvantages: Poor impact resistance at low temperatures, and weak weather resistance.

HDPE is known for its high strength-to-density ratio and impact resistance, making it commonly used in bottles (including blow molding) and corrosion-resistant pipelines.

🔧 Common Material Options and Compatible Methods:

- HDPE (Black/White) – Suitable for CNC machining, vacuum casting, rapid tooling, low-pressure casting, and blow molding.

⚙️ Basic Material Properties:

◆ Flammability: Combustible, deformation temperature 60-82°C.

◆ Advantages: Excellent impact resistance, hygienic and non-toxic, superior water resistance, good chemical resistance, and excellent electrical properties.

◆ Disadvantages: Poor heat resistance, weak weather resistance, and high shrinkage after molding.

Rubber is valued for its flexibility and shock-absorbing properties, making it ideal for products like seals or gaskets that need to withstand continuous bending and pressure. We can also adjust the hardness of the rubber to meet specific requirements.

Bakelite is a high-hardness, heat-resistant thermosetting plastic known for its excellent insulation and chemical resistance. It is commonly used to produce electrical components (such as switches and sockets) and mechanical parts, especially in environments that require heat resistance and insulation.

🔧Common Material Options and Compatible Processes:

Bakelite – CNC machining, injection molding, compression molding

⚙️Basic Material Properties:

◆ Flammability: Flammable, deformation temperature 150-200°C

◆ Advantages: High heat resistance, excellent insulating properties, strong chemical resistance, dimensional stability

◆ Disadvantages: High brittleness, prone to cracking, non-recyclable, challenging to process

Teflon is a thermoplastic material with exceptional chemical stability, known for its high-temperature resistance and extremely low friction coefficient. It is widely used in applications requiring high chemical resistance, such as corrosion-resistant pipe linings, seals, and insulation layers.

🔧Common Material Options and Compatible Processes:

Teflon (PTFE) – CNC machining, turning, compression molding, machining

⚙️Basic Material Properties:

◆ Flammability: Non-flammable, continuous use temperature range from -200 to 260°C

◆ Advantages: Excellent high-temperature resistance, extremely low friction coefficient, strong chemical stability, non-absorbent, excellent electrical insulation

◆ Disadvantages: Difficult to mold and process, low rigidity, limited load-bearing capacity, high thermal expansion coefficient

Metals

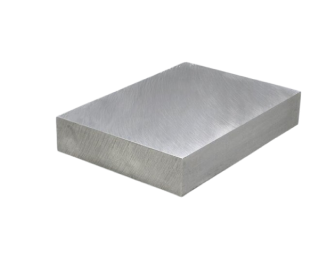

Aluminum is lightweight yet strong, easy to machine, and corrosion-resistant, making it ideal for aerospace and automotive applications where lightweight components are essential.

🔧 Common Material Options and Basic Properties:

- AL6061 – Heat-treatable corrosion-resistant alloy, good machinability, and weldability.

- AL6063 – Extrusion alloy, lower strength.

- AL5052 – Medium-strength alloy, good machinability, excellent fatigue resistance, and high resistance to seawater corrosion.

- AL5083 – High magnesium content, high hardness, and excellent seawater corrosion resistance.

- AL7075 – High strength and hardness, good mechanical properties, and excellent anodizing response.

- ADC 6, 10, 12 – Common aluminum casting alloys.

⚙️ Applicable Processing Methods (not all materials are compatible with every method):

◆ Common machining methods: CNC machining, EDM, aluminum extrusion, aluminum die casting, sand casting, investment casting, low-pressure casting.

Zinc offers excellent corrosion resistance, good fluidity, and is easy to machine with CNC. It is often alloyed with other metals for casting.

🔧 Common Material Options and Basic Properties:

- Zamak 3 – Good mechanical properties, excellent fluidity, the top choice for die casting.

- Zamak 5 – Good mechanical properties and fluidity.

- Zamak 2 – Good mechanical properties, the hardest of the group, but lower dimensional accuracy.

- ZA-8, 12, 27 – Zinc-aluminum alloys, offering high hardness, wear resistance, and deformation resistance.

⚙️ Applicable Processing Methods (not all materials are compatible with every method):

◆ Common machining methods: CNC machining, EDM, metal extrusion, metal die casting, sand casting, investment casting, low-pressure casting.

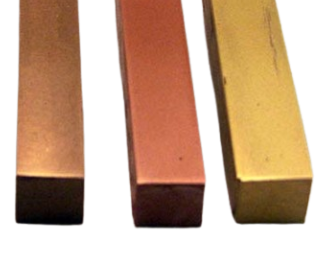

Copper is renowned for its excellent electrical conductivity and thermal properties, making it widely used in electrical components. Bronze (an alloy of copper and tin) offers high corrosion resistance and fatigue strength, commonly used in bearings, bushings, and marine hardware. Brass (an alloy of copper and zinc) is durable with a low friction coefficient, ideal for high-precision components and tools.

🔧 Common Material Options and Basic Properties:

- C1100 (Pure Copper) – High electrical conductivity, thermal conductivity, ductility, corrosion resistance, and weather resistance.

- C17300 (Beryllium Copper) – High heat resistance, ductility before heat treatment, mechanical strength and fatigue resistance after heat treatment, and good electrical conductivity.

- C2700 (Brass) – Good cold forging ability, ductility, suitable for mechanical parts.

- C5191/C5441 (Bronze) – Excellent fatigue resistance, corrosion resistance, and wear resistance.

- C6782 (Brass) – Good hot forging ability, high strength, and corrosion resistance.

- ZQA19-2, 4, 7, 10 – Suitable for copper die casting.

⚙️ Applicable Processing Methods (not all materials are compatible with every method):

◆ Common machining methods: CNC machining, EDM, metal extrusion, metal die casting, sand casting, investment casting, low-pressure casting.

Aluminum-magnesium alloys offer the same strength and hardness as steel but are much lighter, comparable to plastic. With excellent thermal conductivity, they are commonly used in heat-dissipating electronic devices and enclosures.

🔧 Common Material Options and Basic Properties:

- AZ31 – Offers shock resistance, heat absorption, and oil resistance.

- AZ61 – Lighter than AZ31, contains higher aluminum content.

- AZ91D – The most common magnesium alloy, featuring high strength and good casting performance.

- AM60B – In addition to high strength and casting performance, it has good ductility and shock absorption.

⚙️ Applicable Processing Methods (not all materials are compatible with every method):

◆ Common machining methods: CNC machining, EDM, sand casting, investment casting, low-pressure casting.

Stainless steel is renowned for its corrosion resistance and is commonly used in medical devices, robotics, and automated processing equipment.

🔧 Common Material Options and Basic Properties:

- SUS304, 316 – High hardness and corrosion resistance, resistant to rust, commonly used in food-grade and medical-grade applications.

- SUS201 – Basic hardness and corrosion resistance, prone to rusting.

- SUS420, 430, 431 – Basic hardness and corrosion resistance, but magnetic.

⚙️ Applicable Processing Methods (not all materials are compatible with every method):

◆ Common machining methods: CNC machining, EDM, sand casting, investment casting, low-pressure casting.

Titanium boasts the highest strength-to-density ratio among metals and offers excellent corrosion and fatigue resistance, making it commonly used in aerospace, medical devices, and equipment tools.

🔧 Common Material Options and Basic Properties:

- TA1 / TA2 (Commercially Pure Titanium) – Similar mechanical and chemical properties to stainless steel but with lower strength; easy to form, stamp, and weld, with excellent corrosion and oxidation resistance.

- TC4 / Ti-6Al 4V (Titanium Alloy) – Suitable for forging, stamping, and welding, offering excellent heat resistance and corrosion resistance.

⚙️ Applicable Processing Methods (not all materials are compatible with every method):

◆ Common machining methods: CNC machining, EDM, metal die casting.

Silicon carbide (SiC) boasts hardness second only to diamond, with excellent wear resistance, high-temperature tolerance, corrosion resistance, and superior thermal conductivity. It is commonly used in semiconductor manufacturing components, refractory plates, and ceramic bearings.

🔧 Common Material Options and Basic Properties:

- SiC – High hardness and wear resistance, stable chemical and mechanical properties, low energy consumption, and high power efficiency.

- AlSiC – Lightweight like aluminum but with bending strength similar to steel, excellent shock resistance, and high thermal conductivity with low thermal expansion.

⚙️ Applicable Processing Methods (not all materials are compatible with every method):

◆ Common machining methods: CNC machining, EDM.

👉 For more about our latest news, technology and equipment, please follow our official Facebook, X (Twitter) and official blog!